Swintfair

Feria internacional

Iniciar sesión Registrate gratis Membresía Visitantes Globales Post de compra

Estás en: Productos

Maquinaria

Maquinaria farmacéutica

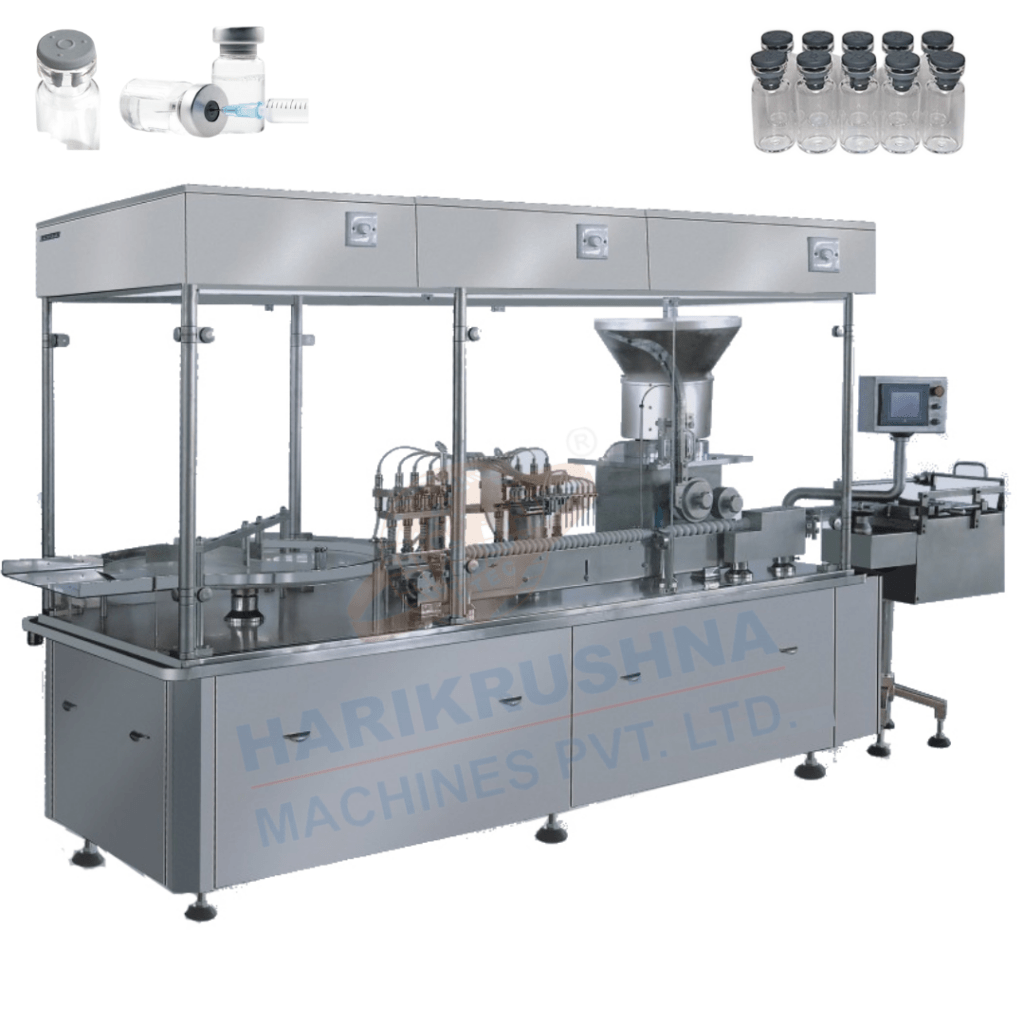

Automatic Combi Air Jet Cleaning and Water Washing Machine

Estás en: Productos

Maquinaria

Maquinaria farmacéutica

Automatic Combi Air Jet Cleaning and Water Washing Machine

Ampliar imagen

Ampliar imagen

Automatic Combi Air Jet Cleaning and Water Washing Machine

Cantidad

Tiempo entrega

| Cantidad | 1 - 1 | > 1 |

|---|---|---|

| Tiempo estimado | 2 días | A negociar |

Alto: 0 CM

Longitud: 0 CM

También te puede interesar

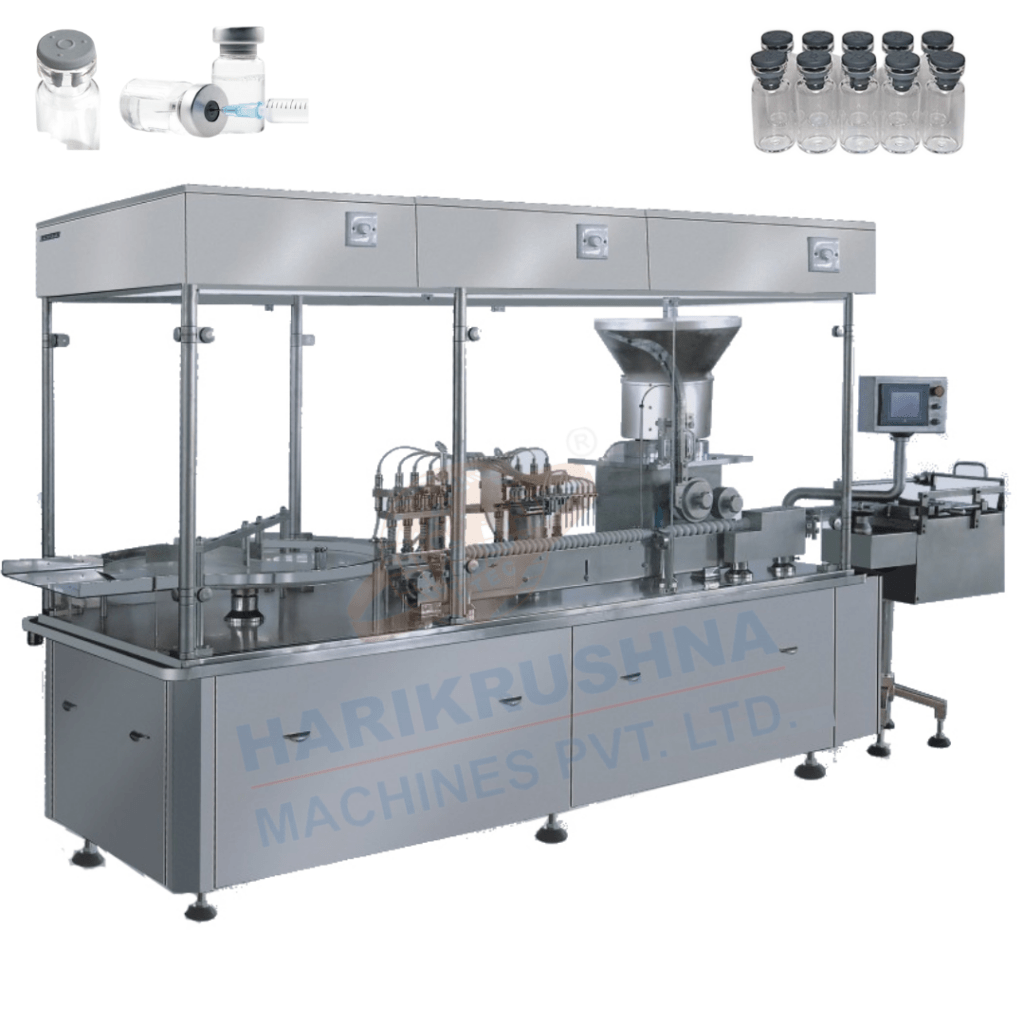

The automatic vial filling machine and rubber bunging machine consist of a basic structure of stainless steel covered with a cabinet safety acrylic cover, laminar air flow, an in-feed turntable machine, a peristaltic pump filling machine, a Delrin slate conveyor, an outfeed turntable, a vibrator bowl and chute for rubber stoppers, pneumatic components, and an electrical panel, an AC drive, a PLC, and an HMI. We also make these machines: Automatic Vial Washing Machines, Automatic Linear Vial Washing Machines, Automatic Rotary Vial Capping Machines, Automatic Vial Sealing Machines, Automatic Dry Powder Injection Filling Machines, Automatic Injectable Liquid Filling Machines, Automatic Injection Vial Filling Machines, Automatic Pharmaceutical Vial Filling Machines, Automatic Vial Cap Sealing Machine, Automatic Vials Filling & Capping Machine, Automatic Filling and Sealing Machine for Vials, Automatic Filling and Sealing Machine for Vials Salient Features: 1) The machine is made compact & versatile as per GMP norms 2) The structure is made out of MS cladding with SS 304 3) Rigid, vibration-free construction for trouble-free performance 4) The contact parts (e.g. filling nozzle) are made of SS316 L 5) The Pharma grade silicon tubes are used for filling & CIP/SIP 6) Easy to clean the base of the machine 7) There is a premium feature called Prime, which sucks the fill material from the storage tank to the nozzle end very quickly. With this facility, clean the filling line (silicon tubes) and fill the peristaltic pump in both directions. 8) The Pharma grade silicon tubes are used for filling and CIP/SIP 9) Easy to clean the base of the machine 10) There is an advanced feature called PRIME, which helps to suck the fill material from the storage tank to the nozzle end very quickly. This facility helps to clean the filling line (silicon tubes) and fill the peristaltic pump in both directions. 11) The machine has a facility of using the PRIME function for all the peristaltic pumps together or individual peristaltic pumps. 12) The process of filling is done by a specially designed filling peristaltic pump, which can serve the purposes of CIP and SIP. 13) Individual pumps can be adjusted and calibrated for the desired volume with an easy-to-operate PLC. 14) Oil-based material runs smoothly without dripping because of a specially designed peristaltic pump with a suck-back facility. 15) Each filling head can work independently and continuously without sacrificing production. 16) No additional parts are required for different vial sizes and filling volumes. 17) There is less product change over time due to less usage of mechanical parts such as syringe set, Teflon seal, gear & chain etc. https://harikrushna.com/product/automatic-vial-filling-and-bunging-machine/

6035.08 USD

1 UNIDADES(MOQ)

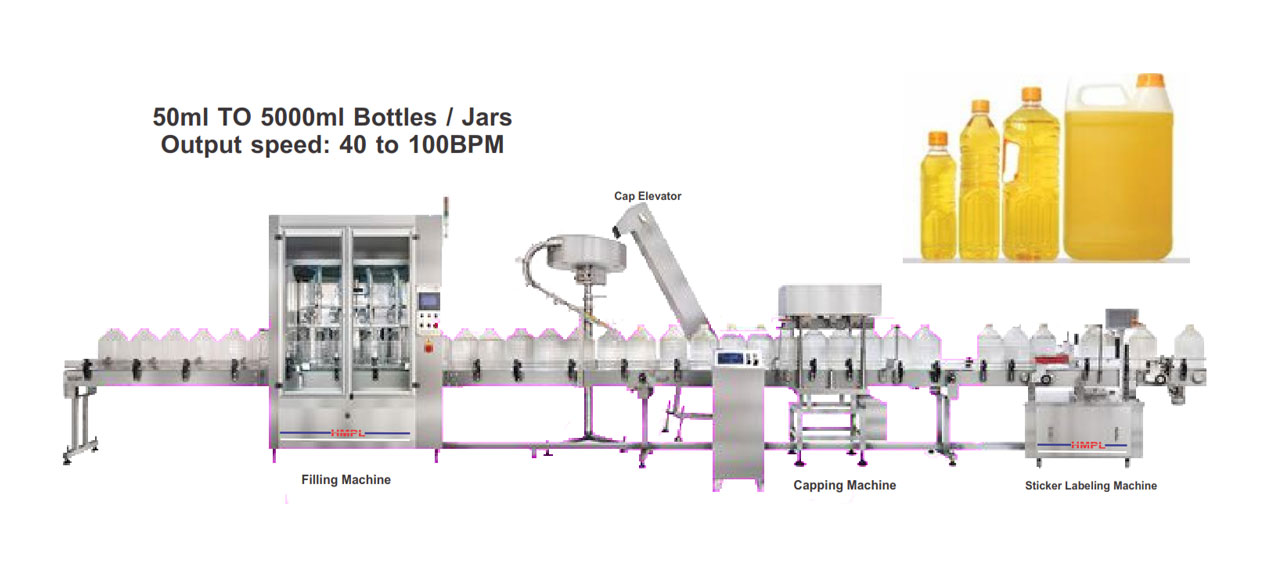

The Automatic Servo Liquid Filling Machine consists of a basic structure, a product transmission belt with an adjustable guide, a material storage tank, a pneumatic bottle stopping facility, SERVO-based Servo Liquid Filling Pumps, Servo Liquid Filling Nozzles, a safety polycarbonate enclosure (optional), an electrical panel, a motor, a PLC and HMI, and an AC drive. A high-low liquid level sensor in the tank is an added advantage. We Are Manufacturers Different Type Of Machine For Liquid Like. High Viscous Liquid / Viscous Liquid Servo Piston Filler Machine Is Suitable For Fill Viscous Liquids Like Viscous Products – Tomato Paste, Ketchup, Jams, Fruit Juices, Vegetable, and Mineral Oils Into a Glass, Pet Bottles, Metallic Or Plastic Containers, Bottle, and Jars. All Viscous Liquids And Capping, Induction Sealer, And Labeling/Sleeve Applicator Line Machinery Are Listed Below For Applications And Industry Installation By Harikrushna Machines Pvt. Ltd., To Pack The Liquid In Different Shapes And Sizes Of Bottles For Eg. Beverages, Cosmetics, Food, And Pesticides. Salient Features: 1) The machine is manufactured or developed following GMP standards. 2) The unit is compact and versatile in design. 3) The structure is made of SS 304. 4) Rigid, vibration-free construction for trouble-free performance. 5) The servo liquid filling machine has a unique design with German technology. 6) The contact parts, such as the filling nozzle and filling pump, are made of SS 316. 7) The pharma- and food-grade PVC-breading tubes are used for liquid filling. 8) Drain the tray around the machine platform. 9) Drip tray under the conveyor. 10) Easy to clean the base of the machine. 11) The storage tank is automatically controlled using high- and low-level sensors. 12) The machine is supplied with easy to clean inbuilt storage tank. 13) The drain valve below the filling tank & collection tray provides for flushing purposes. 14) Auto control valve for the suction line at the plant. 15) Filling is based on a diving system wherein nozzles go inside the bottle and fill it with the desired volume, and nozzles come out of the bottle. 16) A pneumatically (air) operated cylinder performs the diving and blocking of the products. 17) The air pressure indicator attached to the machine indicates a fault with the low pressure of the air supply. 18) A servo-powered filling pump that can quickly suck material from the storage tank to the nozzle end. This facility is for cleaning filling lines and the filling pump. The same function applies to all of the pumps together as well as to individual pumps. 19) An easy-to-use PLC for adjusting fill volume. 20) Each Filling head can be operated & monitored through PLC individually. 21) An air-operated NRV is connected to the discharge line. 22) Each filling head can work independently. 23) No spare parts are required for different product sizes or fill volumes. 24) Product changeover time is too low due to less usage of mechanical parts such as syringe sets, gears, chains, chain wheels, mechanical seals, etc. https://harikrushna.com/product/servo-liquid-filling-machine/

6037.66 EUR

1 UNIDADES(MOQ)

The automatic volumetric liquid filling machine consists of a basic structure, a product transmission belt with an adjustable guide, and an optional safety acrylic cover; a pneumatic or mechanical bottle-stopping facility, nozzles, and syringes, an electrical panel, a motor, a sensor, an AC drive, and mains On and Off. Harikrushna Machines provides a wide range of products, including a semi-automatic volumetric liquid filling machine, a liquid bottle filling machine, an automatic liquid filling machine, an automatic bottle liquid filling machine, and a monoblock liquid filling machine. Automatic Liquid Filling Machine, Viscous Liquid Filling Machine, Automatic Filling and Closing Machine, Monoblock Liquid Filling Machine, Twin Head Liquid Filling Machine, Volumetric Liquid Bottle Filling Machine, Rotary Bottle Liquid Filling Machine, Liquid Filling Machine Manufacturer, Liquid Filling and Capping Machine, High-Speed Liquid Monoblock Machine, Semi-Automatic Volumetric Liquid Filling Machines, Automatic Syrup Filling Machine, Automatic Liquid Filling Machine, Twin Track Viscous Liquid Filling Machine, High-Speed Liquid Monoblock Machine, Liquid Bottle Filling Machine, Automatic Liquid Filling Machine, Fully Automatic Liquid Filling Machine, Multi-Head Liquid Filling Machine, High-Speed Liquid Filling Machine, Viscous Product Filling Machine, Automatic Paste Filling Machine, Automatic Tube Filling Machine, Automatic Ointment Filling Machine, Automatic Honey Filling Machine, Automatic Shampoo Filling Machine, Automatic Hair Oil Filling Machine, Automatic Gel Filling Machine, Liquid Soap Filling Machine, Honey Filling Machine, Sauce Filling Machine, Automatic Wick Inserting Machine, Rotary Oil Filling Line, With Liquid Filler are Most important Equipment for Liquid Packing Line and Industries. e.g., cosmetics, beverages, pharmaceuticals, and pesticides. Salient Features: 1) The filling machine is manufactured or developed following GMP standards. 2) The structure is made of MS clad with SS 304. 3) Rigid, vibration-free construction for trouble-free performance 4) SS matte-finished body. 5) The pharma- and food-grade PVC-braided tubes are used for filling purposes. 6) Place a drain tray around the machine platform. 7) Drip tray under the conveyor. 8) An elegant and simple control panel gives you complete control over the operation. 9) All interlocks must be shown on the control panel. 10) Fill accuracy of less than 1% on a single dose. 11) If there is no bottle, then there is no filling system; the machine should stop at the home position. 12) Diving nozzle device. 13) Minimal time required to transition from one bottle or fill size to another. 14) A self-lubricating UHMW-PE guide profile for stainless steel slat chains provides a low friction wear surface and smooth, noiseless conveying. 15) pneumatic/mechanical bottle-stopping arrangement 16) Synchronized two AC drives for the motor and conveyor belt. 17) SS measurement scale for filling volume adjustment. https://harikrushna.com/product/automatic-volumetric-liquid-filling-machine/

6042.34 USD

1 UNIDADES(MOQ)

The Semi-Automatic Volumetric Liquid Filling Machine—Table Top consists of the main structure, product holding mechanism, nozzles and syringes, electrical panel, motor, and mains ON/OFF. Salient Features: 1) The machine is manufactured or developed following GMP standards. 2) The structure is made of MS clad with SS 304. 3) Rigid, vibration-free construction for trouble-free performance. 4) Elegantly matte-finished SS 304 bodies 5) All contact parts are made from SS 316. 6) Reciprocate the filling nozzle with the self-centring device to avoid foaming. 7) The pharma- and food-grade PVC-breading tubes are used for the filling. 8) Minimum change over time from one size to another bottle or fill size 9) SS measurement scale for filling volume adjustment. 10) Filling precision of 1% in a single dose 11) The flow of liquid can change as per requirements. 12) One-of-a-kind tabletop machine Technical Specification: Model: HMPL-VLF-2 1) Bottle size (Ø): 15 mm Ø to 90 mm Ø 2) Output speed: 20 to 25 Bottles/Minute (Depending on the viscosity of liquid and manual loading & unloading) 3) Number of Heads or Syringes: 2 No. 4) Fill Size: 10 ml to 1000 ml Round Glass/PET Bottles (With Required Change Parts) 5) Power Supply: Single Phase / 230 V AC / 50 Hz 6) Net Weight Approx.: 75 Kg 7) Dimensions: Table Top https://harikrushna.com/product/semi-automatic-volumetric-liquid-filling-machine-table-top/

3023.25 EUR

1 UNIDADES(MOQ)

The semi-automatic piston filling machine consists of the main structure, filling nozzle, hopper, pneumatic cylinder, pedal switch, and mains ON/OFF. Salient Features: 1) The piston filling machine is manufactured or developed following GMP standards. 2) The structure is made of SS 304 with a matte finish. 3) The contact parts are made of SS 316. 4) Rigid, vibration-free construction for trouble-free performance. 5) The machine is run with air where an electric supply is not required. 6) The unit is controlled by compressed air. 7) Different filling volumes or products do not necessitate the different parts. 8) Specially designed pneumatic cylinder-operated nozzle with a plunger to avoid dripping. 9) The machine is used for filling various sizes of products. 10) Use the emergency on/off switch to prevent an accident. 11) User-friendliness and scalability 12) Simple screw adjustment and cleaning. 13) All pneumatic connections FESTO, SMC, and Janatics make. 14) Operation in both Auto and Manual Modes 15) A 20-Kg SS-316 single-wall hopper. Technical Specifications: Model: HMPL–SPF 1) Filling Volume: 50 - 500 ml 2) Filling Accuracy: ± 1 to 1.5% of Filling Weight 3) Speed (BPM): 10 to 15 Products/Minute (Depending on the viscosity of the material & manual loading) 4) Air Pressure: 5 to 8 Kg/cm² 5) Air Consumption: 50 L/Min 6) Net Weight: 28 Kg 7) Dimensions (L x W x H )mm: 1080 x 320 x 410 https://harikrushna.com/product/semi-automatic-piston-filling-machine-table-top/

3025.2 EUR

1 UNIDADES(MOQ)

Logistics

Logistics

16 productos publicados

16 productos publicados

Resumen

Especificaciones

| Lugar de Origen: | Ahmedabad, India |

| Referencia producto: | Washing Machinery |

| HSCode: | |

| Stock disponible: | 1 UNIDADES |

| Pedido mínimo: | 1 UNIDADES |

| Pago: | T/T |

| Tiempo entrega: | 2 días |

| Keywords: | combi-air jet washing machine automatic combi-air jet washing machine |

| Nombre producto: |

Automatic Combi Air Jet Cleaning and Water...

|

| Unidad de venta: | UNIDADES |

Embalaje y Entrega

| Tipo de paquete | PX - PALLET |

||||||

| Unidades por paquete | 0 UNIDADES / PX - PALLET |

||||||

| Peso por bulto | 0 KG |

||||||

| Dimensiones paquete unitario | 0x0x0 CM | ||||||

| Tiempo entrega |

|

||||||

| Capacidad adquisición |

Descripción

The high-speed linear bottle washer is used in the pharmaceutical, food, and beverage industries and is best suited for round or flat bottles. The automatic loading arrangement facilities use a feed conveyor to load bottles onto a turntable or a pushing device to push bottles, which saves manual work because bottles are fed into pockets automatically. The automatic unloading mechanism consists of unloading the bottle to continue to the turntable (optional). Salient Features: 1) The machine is built or developed following GMP standards. 2) The structure is made of MS clad with SS 304, including the frame. 3) Rigid, vibration-free construction for trouble-free performance 4) High-pressure spray nozzles ensure the perfect wash of bottles. 5) Interchangeable wash sequences 6) With the help of interchangeable parts, the machine can handle round and flat glass bottles. 7) All parts coming into contact with washing zones or jets are made from SS 316L materials. 8) Pumps and tanks are mounted on a portable stand for easy maintenance and cleaning. 9) Water recycling arrangements are possible as per the customer's needs. 10) A large-capacity centrifugal pump for cleaning larger containers 11) A third tank and pump can be fitted (optional). 12) The most important and well-known pneumatic components are Festo/SMC/Janatics, Bonfiglioli/Motovario/Rotomotive for AC motors, Delta for AC drives, and MCB and relay CE for electrical and electronic components. Technical Specifications: Model: HMPL–WAVC 1) Bottle Type & MOC: Round Glass/PET Bottles 2) Bottle Size: 15 mm Ø to 70 mm Ø Height: 50 mm to 270 mm Neck Ø: 21 mm to 25 mm 3) No. of Row: 10 4) Output Speed: Up to 150 Bottles/Minute 5) Tank Capacity: 45 Liters of SS 316 L (2 Nos) 6) Wash Cycle: 1st Inner Water Wash + 2nd Outer & Inner Water Wash + outer Air & Inner Air +Vacuum Cleaning 7) Cycle Timing: 1 Second for each wash + 1.5 seconds for travelling 8) Water Consumption: 500 Liters / Hour 9) Working Hight: 875 ± 50 mm Adjustable 10) Electrical Specification: Semi Servo Motor, 1 HP, 415 Volts, 50 Hz, with Backless Gearbox Pump Two Nos. 1 HP x 3 = 3 HP; 415 volts; 50 Hz Conveyor 0.5 HP / 415 Volts / 50 Hz 11) Air Consumption: 5 CFM 4 to 6 Kg/Cm2 (As per customer needs) 12) Net Weight: 550 kg (approx. 13) Dimensions: 2770 mm L x 1230 mm W x 1300 mm H (approx. 14) Change Parts: Bottle Rack & Turn Table Guide Set https://harikrushna.com/product/combi-airjet-water-washing-machine/

Imágenes

Enviar un mensaje al proveedor

Resumen Empresa

Imágenes empresa

| Nombre de empresa: | Harikrushna Machines Pvt. Ltd. |

| Tipo de empresa: | Otros |

| Total trabajadores: | +200 |

| Año fundación: | 1999 |

| País y ciudad | Ahmedabad, India |

| Categoría de empresa: | Maquinaria |

| Tamaño de oficina: | 143 |

| Principales productos: |

filling machine, capping machine, bottling plant |

Detalles operacionales

Rendimiento empresarial

Tiempo de respuesta

<= 6 horas

Tasa entrega

100%

Transacciones

En trámite

Índice Vendedor

| Idiomas hablados | Español / Inglés |

| Ingresos anuales totales | No especificado |

| Términos entrega aceptados | EXW, FOB y CIF |

| Métodos de pago aceptados | T/T y LC |

| Divisa de pago aceptada | EUR y USD |

| Puerto más cercano | BARCELONA |

Capacidad Internacional

| America del Norte | |

| Sudesete Asiático | |

| Oriente Medio | |

| America Central | |

| Sur de Asia | |

| Sudamérica | |

| Africa |

| Este de Asia | |

| Europa del Norte | |

| Mercado Doméstico | |

| Europa del Este | |

| Oceanía | |

| Europa Atlántica | |

| Europa Mediterránea |

EXW

FCA

CPT

CIP

FAS

FOB

CFR

CIF

DPU

DAP

DDP

Presentación

Descripción de la empresa

Harikrushna Machines Pvt. Ltd. is an ISO 9001:2015 and CE-certified manufacturer and exporter of liquid processing and liquid packaging machines in India. We are one of the most preferred and trusted solution providers for liquid packaging machines. We are a manufacturer and exporter of advanced liquid processing and packaging machinery for pharmaceuticals, dairy, food and beverage, edible oil, distilleries, cosmetics, lubricants, pesticides, and other allied industries. HARIKRUSHNA MACHINES PVT. LTD. (HMPL)'s headquarters office is in Vatva GIDC, Ahmedabad, Gujarat, India. HMPL is one of the most preferred business hubs across the globe. We have a state-of-the-art and advanced manufacturing unit in Ahmedabad. HMPL is the proud patron of over 11500 installations in 58 countries, including India. We have a wide range of semi-automatic and fully automatic liquid packaging machines for washing, filling, capping, sealing, labelling, cartooning, and tube filling and sealing. We provide liquid packaging machines as per liquid-based manufacturing business needs. Harikrushna Machines is the leading manufacturer and exporter of Oral Liquid/ Syrup/ Suspension Manufacturing Plant and Ointment, Cream, Lotion, Shampoo, and Toothpaste Manufacturing Plant in India. We are the leading Turnkey Project Solution Provider in India. We provide Beverages Turnkey Projects, Dairy Turnkey Projects, Cosmetic Turnkey Projects and Pharmaceutical Turnkey Projects globe. We have provided top-notch liquid packaging machines to well-known brands, start-up businesses, and Small and Medium Enterprises (SMEs). Harikrushna Machines Pvt. Ltd. provides complete Mineral Water Turnkey Project solutions like Automatic Rotary (3 in 1) Rinsing/ Filling and Capping Machines, Mineral Water Turnkey Project Providers, Water Jar Rinsing, Filling and Capping Machines, Commercial Reverse Osmosis Systems, Semi-Automatic Blow Moulding Machine, Automatic Blow Moulding Machine, Automatic Water Bottle Filling Machine, Manual Batch Coding Machine, Automatic Batch Coding Machine, Automatic Water Pouch Packing Machine, Sticker Labelling Machine, Automatic BOPP Labelling Machine, Shrink Sleeve Labelling Machine, Pre Fill Syringe (PFS) Machinery, Semi-Automatic Shrink Wrapping Machine, Automatic Shrink Wrapping Machine, Juice Plant Project and Carbonated Soft Drinks Project and also provides Turn Table, Roller Conveyor, Packing Conveyor, Visual Inspection Conveyor, Bend Conveyor and Magnifying Glass Inspection Conveyor. Harikrushna Machines Pvt. Ltd. provides complete packaging lines for various industries. Ampoule Packaging Line, Injectable Vial Liquid Packaging Line, Complete IV Bottle Packaging Line (Large Volume Parenterals), Complete IV Bottle Packaging Line (Small Volume Parenterals), Lotion OR Cream Packaging Line, Tablet/ Capsule Packaging Line and Eye-Ear Drop Packaging Line for Pharmaceutical Industries. Automatic Liquid Packaging Line - Wide Range of Liquid Filling Machines. Flavoured OR Plain Milk Packaging Line for Glass Bottle, Flavoured Milk OR Butter Milk OR Lassi Packaging Line for PP Bottles. Pesticides FLP Packaging Line, Edible Oil Packaging Line, Lubricant Oil Packaging Line, Mineral Water OR Juice Packaging Line and Liquor Packaging Line (Linear and Rotary Machines.

Productos populares del vendedor

The automatic vial filling machine and rubber bunging machine consist of a basic structure of stainless steel covered with a cabinet safety acrylic cover, laminar air flow, an in-feed turntable machine, a peristaltic pump filling machine, a Delrin slate conveyor, an outfeed turntable, a vibrator bowl and chute for rubber stoppers, pneumatic components, and an electrical panel, an AC drive, a PLC, and an HMI. We also make these machines: Automatic Vial Washing Machines, Automatic Linear Vial Washing Machines, Automatic Rotary Vial Capping Machines, Automatic Vial Sealing Machines, Automatic Dry Powder Injection Filling Machines, Automatic Injectable Liquid Filling Machines, Automatic Injection Vial Filling Machines, Automatic Pharmaceutical Vial Filling Machines, Automatic Vial Cap Sealing Machine, Automatic Vials Filling & Capping Machine, Automatic Filling and Sealing Machine for Vials, Automatic Filling and Sealing Machine for Vials Salient Features: 1) The machine is made compact & versatile as per GMP norms 2) The structure is made out of MS cladding with SS 304 3) Rigid, vibration-free construction for trouble-free performance 4) The contact parts (e.g. filling nozzle) are made of SS316 L 5) The Pharma grade silicon tubes are used for filling & CIP/SIP 6) Easy to clean the base of the machine 7) There is a premium feature called Prime, which sucks the fill material from the storage tank to the nozzle end very quickly. With this facility, clean the filling line (silicon tubes) and fill the peristaltic pump in both directions. 8) The Pharma grade silicon tubes are used for filling and CIP/SIP 9) Easy to clean the base of the machine 10) There is an advanced feature called PRIME, which helps to suck the fill material from the storage tank to the nozzle end very quickly. This facility helps to clean the filling line (silicon tubes) and fill the peristaltic pump in both directions. 11) The machine has a facility of using the PRIME function for all the peristaltic pumps together or individual peristaltic pumps. 12) The process of filling is done by a specially designed filling peristaltic pump, which can serve the purposes of CIP and SIP. 13) Individual pumps can be adjusted and calibrated for the desired volume with an easy-to-operate PLC. 14) Oil-based material runs smoothly without dripping because of a specially designed peristaltic pump with a suck-back facility. 15) Each filling head can work independently and continuously without sacrificing production. 16) No additional parts are required for different vial sizes and filling volumes. 17) There is less product change over time due to less usage of mechanical parts such as syringe set, Teflon seal, gear & chain etc. https://harikrushna.com/product/automatic-vial-filling-and-bunging-machine/

6035.08 USD

1 UNIDADES(MOQ)

The Automatic Servo Liquid Filling Machine consists of a basic structure, a product transmission belt with an adjustable guide, a material storage tank, a pneumatic bottle stopping facility, SERVO-based Servo Liquid Filling Pumps, Servo Liquid Filling Nozzles, a safety polycarbonate enclosure (optional), an electrical panel, a motor, a PLC and HMI, and an AC drive. A high-low liquid level sensor in the tank is an added advantage. We Are Manufacturers Different Type Of Machine For Liquid Like. High Viscous Liquid / Viscous Liquid Servo Piston Filler Machine Is Suitable For Fill Viscous Liquids Like Viscous Products – Tomato Paste, Ketchup, Jams, Fruit Juices, Vegetable, and Mineral Oils Into a Glass, Pet Bottles, Metallic Or Plastic Containers, Bottle, and Jars. All Viscous Liquids And Capping, Induction Sealer, And Labeling/Sleeve Applicator Line Machinery Are Listed Below For Applications And Industry Installation By Harikrushna Machines Pvt. Ltd., To Pack The Liquid In Different Shapes And Sizes Of Bottles For Eg. Beverages, Cosmetics, Food, And Pesticides. Salient Features: 1) The machine is manufactured or developed following GMP standards. 2) The unit is compact and versatile in design. 3) The structure is made of SS 304. 4) Rigid, vibration-free construction for trouble-free performance. 5) The servo liquid filling machine has a unique design with German technology. 6) The contact parts, such as the filling nozzle and filling pump, are made of SS 316. 7) The pharma- and food-grade PVC-breading tubes are used for liquid filling. 8) Drain the tray around the machine platform. 9) Drip tray under the conveyor. 10) Easy to clean the base of the machine. 11) The storage tank is automatically controlled using high- and low-level sensors. 12) The machine is supplied with easy to clean inbuilt storage tank. 13) The drain valve below the filling tank & collection tray provides for flushing purposes. 14) Auto control valve for the suction line at the plant. 15) Filling is based on a diving system wherein nozzles go inside the bottle and fill it with the desired volume, and nozzles come out of the bottle. 16) A pneumatically (air) operated cylinder performs the diving and blocking of the products. 17) The air pressure indicator attached to the machine indicates a fault with the low pressure of the air supply. 18) A servo-powered filling pump that can quickly suck material from the storage tank to the nozzle end. This facility is for cleaning filling lines and the filling pump. The same function applies to all of the pumps together as well as to individual pumps. 19) An easy-to-use PLC for adjusting fill volume. 20) Each Filling head can be operated & monitored through PLC individually. 21) An air-operated NRV is connected to the discharge line. 22) Each filling head can work independently. 23) No spare parts are required for different product sizes or fill volumes. 24) Product changeover time is too low due to less usage of mechanical parts such as syringe sets, gears, chains, chain wheels, mechanical seals, etc. https://harikrushna.com/product/servo-liquid-filling-machine/

6037.66 EUR

1 UNIDADES(MOQ)

The automatic volumetric liquid filling machine consists of a basic structure, a product transmission belt with an adjustable guide, and an optional safety acrylic cover; a pneumatic or mechanical bottle-stopping facility, nozzles, and syringes, an electrical panel, a motor, a sensor, an AC drive, and mains On and Off. Harikrushna Machines provides a wide range of products, including a semi-automatic volumetric liquid filling machine, a liquid bottle filling machine, an automatic liquid filling machine, an automatic bottle liquid filling machine, and a monoblock liquid filling machine. Automatic Liquid Filling Machine, Viscous Liquid Filling Machine, Automatic Filling and Closing Machine, Monoblock Liquid Filling Machine, Twin Head Liquid Filling Machine, Volumetric Liquid Bottle Filling Machine, Rotary Bottle Liquid Filling Machine, Liquid Filling Machine Manufacturer, Liquid Filling and Capping Machine, High-Speed Liquid Monoblock Machine, Semi-Automatic Volumetric Liquid Filling Machines, Automatic Syrup Filling Machine, Automatic Liquid Filling Machine, Twin Track Viscous Liquid Filling Machine, High-Speed Liquid Monoblock Machine, Liquid Bottle Filling Machine, Automatic Liquid Filling Machine, Fully Automatic Liquid Filling Machine, Multi-Head Liquid Filling Machine, High-Speed Liquid Filling Machine, Viscous Product Filling Machine, Automatic Paste Filling Machine, Automatic Tube Filling Machine, Automatic Ointment Filling Machine, Automatic Honey Filling Machine, Automatic Shampoo Filling Machine, Automatic Hair Oil Filling Machine, Automatic Gel Filling Machine, Liquid Soap Filling Machine, Honey Filling Machine, Sauce Filling Machine, Automatic Wick Inserting Machine, Rotary Oil Filling Line, With Liquid Filler are Most important Equipment for Liquid Packing Line and Industries. e.g., cosmetics, beverages, pharmaceuticals, and pesticides. Salient Features: 1) The filling machine is manufactured or developed following GMP standards. 2) The structure is made of MS clad with SS 304. 3) Rigid, vibration-free construction for trouble-free performance 4) SS matte-finished body. 5) The pharma- and food-grade PVC-braided tubes are used for filling purposes. 6) Place a drain tray around the machine platform. 7) Drip tray under the conveyor. 8) An elegant and simple control panel gives you complete control over the operation. 9) All interlocks must be shown on the control panel. 10) Fill accuracy of less than 1% on a single dose. 11) If there is no bottle, then there is no filling system; the machine should stop at the home position. 12) Diving nozzle device. 13) Minimal time required to transition from one bottle or fill size to another. 14) A self-lubricating UHMW-PE guide profile for stainless steel slat chains provides a low friction wear surface and smooth, noiseless conveying. 15) pneumatic/mechanical bottle-stopping arrangement 16) Synchronized two AC drives for the motor and conveyor belt. 17) SS measurement scale for filling volume adjustment. https://harikrushna.com/product/automatic-volumetric-liquid-filling-machine/

6042.34 USD

1 UNIDADES(MOQ)

The Semi-Automatic Volumetric Liquid Filling Machine—Table Top consists of the main structure, product holding mechanism, nozzles and syringes, electrical panel, motor, and mains ON/OFF. Salient Features: 1) The machine is manufactured or developed following GMP standards. 2) The structure is made of MS clad with SS 304. 3) Rigid, vibration-free construction for trouble-free performance. 4) Elegantly matte-finished SS 304 bodies 5) All contact parts are made from SS 316. 6) Reciprocate the filling nozzle with the self-centring device to avoid foaming. 7) The pharma- and food-grade PVC-breading tubes are used for the filling. 8) Minimum change over time from one size to another bottle or fill size 9) SS measurement scale for filling volume adjustment. 10) Filling precision of 1% in a single dose 11) The flow of liquid can change as per requirements. 12) One-of-a-kind tabletop machine Technical Specification: Model: HMPL-VLF-2 1) Bottle size (Ø): 15 mm Ø to 90 mm Ø 2) Output speed: 20 to 25 Bottles/Minute (Depending on the viscosity of liquid and manual loading & unloading) 3) Number of Heads or Syringes: 2 No. 4) Fill Size: 10 ml to 1000 ml Round Glass/PET Bottles (With Required Change Parts) 5) Power Supply: Single Phase / 230 V AC / 50 Hz 6) Net Weight Approx.: 75 Kg 7) Dimensions: Table Top https://harikrushna.com/product/semi-automatic-volumetric-liquid-filling-machine-table-top/

3023.25 EUR

1 UNIDADES(MOQ)

The semi-automatic piston filling machine consists of the main structure, filling nozzle, hopper, pneumatic cylinder, pedal switch, and mains ON/OFF. Salient Features: 1) The piston filling machine is manufactured or developed following GMP standards. 2) The structure is made of SS 304 with a matte finish. 3) The contact parts are made of SS 316. 4) Rigid, vibration-free construction for trouble-free performance. 5) The machine is run with air where an electric supply is not required. 6) The unit is controlled by compressed air. 7) Different filling volumes or products do not necessitate the different parts. 8) Specially designed pneumatic cylinder-operated nozzle with a plunger to avoid dripping. 9) The machine is used for filling various sizes of products. 10) Use the emergency on/off switch to prevent an accident. 11) User-friendliness and scalability 12) Simple screw adjustment and cleaning. 13) All pneumatic connections FESTO, SMC, and Janatics make. 14) Operation in both Auto and Manual Modes 15) A 20-Kg SS-316 single-wall hopper. Technical Specifications: Model: HMPL–SPF 1) Filling Volume: 50 - 500 ml 2) Filling Accuracy: ± 1 to 1.5% of Filling Weight 3) Speed (BPM): 10 to 15 Products/Minute (Depending on the viscosity of the material & manual loading) 4) Air Pressure: 5 to 8 Kg/cm² 5) Air Consumption: 50 L/Min 6) Net Weight: 28 Kg 7) Dimensions (L x W x H )mm: 1080 x 320 x 410 https://harikrushna.com/product/semi-automatic-piston-filling-machine-table-top/

3025.2 EUR

1 UNIDADES(MOQ)

Incoterms

Incoterms